Our Catalysts

Pioneered at Carnegie Mellon, Dot Catalysts are powered by TAML chemistry— patented chemical additives that bio-mimic the body’s chemistry to boost oxidation and enhance performance in systems using hydrogen peroxide, hypochlorite, electrochemical oxidation, and more.

Dot AMP

Highly active catalyst that works with variety of oxidants to enhance cleaning processes.

-

•••

Optimal Oxidant Pairings(s): Chlorine-based oxidants

•••

Appearance: Orange/Brown

Particle Size: 120 - 1720μm

Active Content: 100%

Water Soluble: Yes

Optimal PH: 6-12

Deactivation: ##of turnovers range??

Dot AMP+

Highly active oxidation catalyst that works with odidants to enhance cleaning processes. Extended lifecycle is ideal for pairing with peroxide and percarbonate processes.

-

•••

Optimal Oxidant Pairings(s): Peroxide, Percarbonate, and Chlorine-based oxidants

•••

Appearance: Orange/Brown

Particle Size: 120 - 1720μm

Active Content: 100%

Water Soluble: Yes

Optimal PH: 6-12

Deactivation: ##of turnovers range??

Dot Activator

Designed to significantly reduce the amount of oxidant needed in cleaning products, while enhancing efficiency and performance.

-

Dot Activator currently powers the Dot Cleaner brand of products for mold remediation, waterproofing, restoration, facility management, and more.

Dot Activator enables professionals to tackle tough jobs and tough cleaning problems with less chemical, less odor, less waste, and simpler logistics.

Visit DotCleaner.com to see range of products enhanced by Activator.

FEATURED INDUSTRY USING DOT CATALYSTS

Commercial Laundry

Dot Catalysts can be used to reduce laundry system temperatures, improve stain & odor removal, increase textile longevity, reduce dye transfer, improve fugitive dye removal, and more.

Dot Catalysts, powered by TAML Chemistry, make oxidation reactions exponentially more efficient.

TAML catalysts feature a macrocyclic ligand that stabilizes a metal ion, accelerating oxidation while preventing deactivation. These molecules pair with an oxidant, capture an oxygen atom, and rapidly deliver it to the target—mimicking peroxidase enzymes in the body. Once their job is done, TAML catalysts break down into natural elements, no longer remaining active in the environment.

This process significantly reduces the need for excess chemical oxidants, forming the core of our Dot Catalyst technology.

Contact Us

Would you like to learn more about Dot Catalysts? Please contact our development team for partnership and catalyst information.

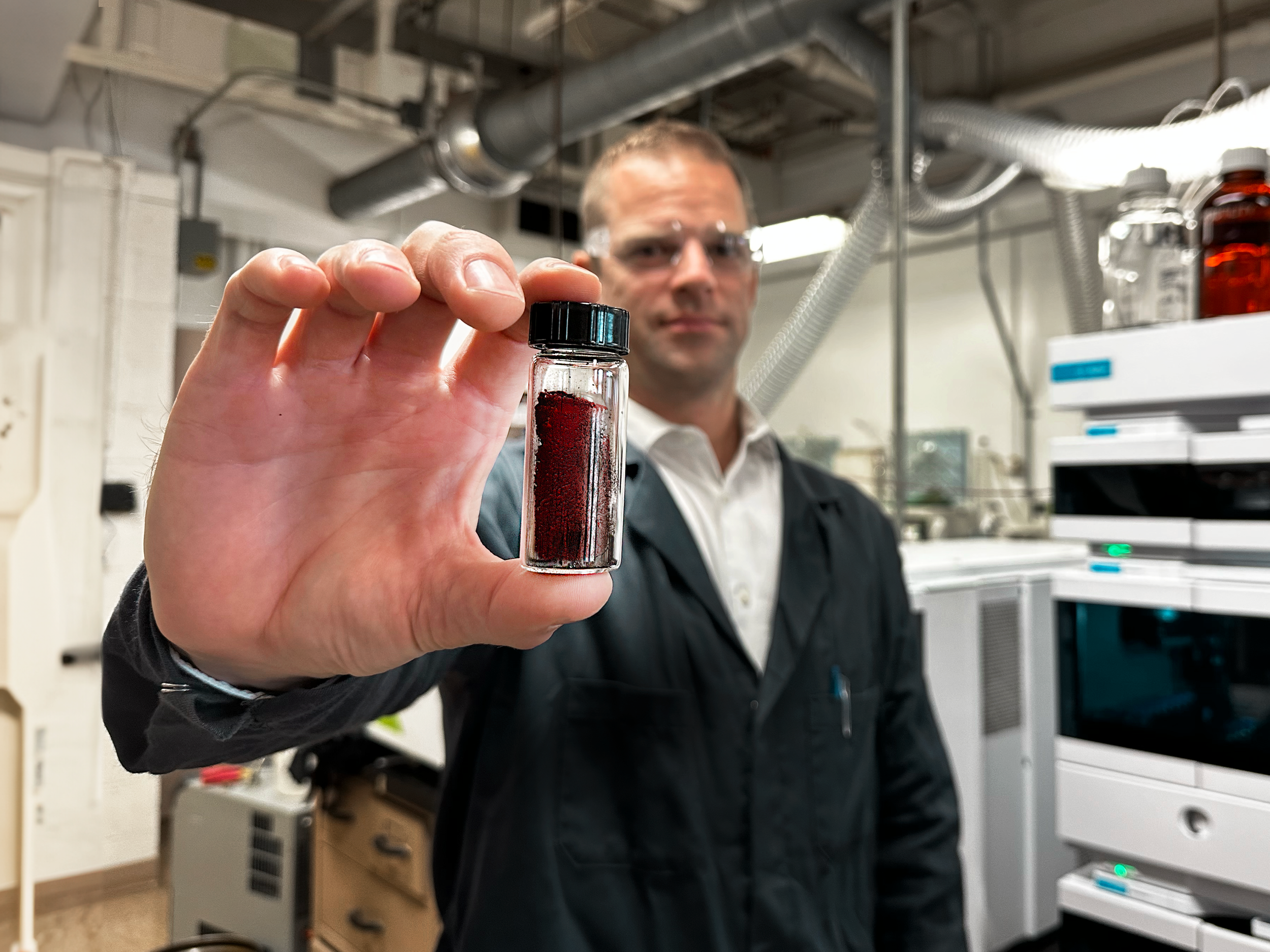

Stephan Ashendorf

Dot Catalysts Lead

sashendorf@sudoc.com

480.239.0462